The slew bearing is one of the common key components in industrial equipment. The correct installation has an important impact on the operating stability and life of the equipment. However, because the installation process involves multiple steps and complex technical requirements, it is necessary to strictly follow certain methods and precautions during the installation process. This article will introduce the installation methods and installation precautions of the rotary support bearing to help readers perform the installation operation correctly to ensure the normal operation and safety of the equipment.

1. The way to turn the bearing bearing bearing support method

1. Preparation: Before starting installation, prepare the required tools and equipment, including lifting equipment, measurement tools, lubricating fat, etc. At the same time, check the state of the bearing and installation position to ensure that the surface is smooth, no damage and impurities.

2. Determine the installation location: According to the design drawings and requirements of the equipment, determine the installation location of the rotary support bearing, and make the necessary preparations at this location, such as cleaning and flattening.

3. Installation base: If you need to install a base, fix the base to the installation position and adjust the level instrument to ensure that the level of the base is stable.

4. Installation Bearing: Put the rotary support for the bearing in the installation hole of the base or equipment to ensure that the bearings are fully matched with the base or installation hole, and the surface of the base or installation hole is well exposed to the bearings.

5. Adjust position: Use the measurement tool to check the installation position and position of the bearings to ensure that the bearings are in the correct position and angle. Make fine -tuning as needed until the required installation accuracy.

6. Fixed bearing: After the position of the bearing is correct, use bolts or other fixed parts to fix the bearing firmly on the base or installation hole to ensure that the bearings will not move or shake during the use process.

7. Lubrication: After the installation is completed, add an appropriate amount of lubricating fat or lubricating oil according to the requirements and use environment of the bearings to ensure the lubrication and cooling effect of the bearing during operation.

8. Check: After completing the installation, perform the final check and adjustment of ZUI to ensure that the bearing is installed correctly, fixed firmly, no loose or deviation, and can operate normally.

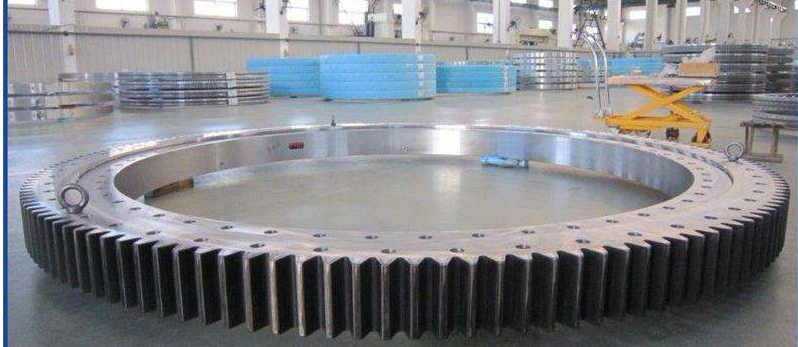

Slewing ring

2. Precautions for the installation of the rotary support bearing bearing

1. Select the right installation tool: During the installation process, select the right lifting equipment and fixed tools to ensure that the installation operation can be safely and stable.

2. Pay attention to the installation environment: When installing, pay attention to the cleaning and quietness of the environment, avoid interference caused by debris and noise to the installation process, and affect the quality of installation.

3. Installation strictly in accordance with regulations: During the installation process, operate strictly in accordance with the design requirements and installation steps of the equipment, and shall not change or omit any steps at will.

4. Bearing lubrication: When adding lubricating fat or lubricating oil, pay attention to choosing the right lubricant and ensure the smoothness and effectiveness of the lubricating system to extend the service life of the bearing.

5. Installation accuracy: Pay attention to maintaining the installation accuracy of the bearings when installing, and minimize the installation error to ensure the normal operation and stability of the equipment.

6. Prevent damage: During the installation process, be careful of the surface of the bearing and installation position to avoid collision and damage, and ensure the integrity and stability of the installation.

7. Quality inspection: After completing the installation, perform the necessary quality testing and testing to ensure that the quality of the bearing installation meets the requirements and can operate normally.

8. Safety: In the entire installation process, we must always put safety in the first place, strictly abide by the safety operation regulations, and ensure that the installation process is safe and reliable.

In summary, the installation of the rotary support bearing bearing is not only related to the performance and life of the equipment, but also directly affects production efficiency and safety production. Through the installation methods and precautions described in this article, readers can more clearly understand the installation process of the rotary support bearing, and avoid common installation errors and errors in practical operation. In future work, we should continue to pay attention to the details and quality of installation operations, continuously improve the level of installation technology, and ensure the stable operation and safety production of the equipment.